A bill of materials (also known as a BOM) is a comprehensive document that contains a list of the materials that are needed to manufacture a product.

It also includes step-by-step instructions on how to make and assemble that item. A BOM is drafted before production begins because it allows the manufacturer to check whether the materials are readily available.

The BOM is also used as a reference by suppliers, workers, purchasing officers, and regulators to ensure certain internal and statutory requirements are followed correctly. Depending on the type of product that’s being manufactured, the BOM may either be publicly available or it might remain confidential as a unique proprietary document.

Continue reading to learn more about what a bill of materials is, why it’s important, and the type of information it includes.

In this post:

Bill of materials explained

Put simply, a bill of materials (BOM) acts as a blueprint for how to manufacture a particular product. It includes a list of the specific ingredients/materials and the corresponding quantities that are required to produce or build that item(s). It serves as a centralised source of information that suppliers and workers use as a reference when manufacturing a product.

It’s crucial to create a product’s BOM before the manufacturing or assembly process begins. This is to ensure all of the necessary materials are available in the company’s existing inventory and/or that the supplier has them in stock. Failure to draft the BOM at this early stage could result in the production schedule being delayed, which can be inconvenient, disruptive and very costly.

For obvious reasons, BOMs vary depending on the type of project or products being manufactured. While the bill of materials is essential to the production process, not every department in a company will have to refer to it. Some of the common divisions that will need to consult the BOM include the design, engineering, and manufacturing departments.

The various stages of the production process require different types of materials. This is why the BOM always specifies the type of materials and their corresponding quantities at each stage of the manufacturing process. Without this information, it would be difficult to keep track of material costs and the production process wouldn’t run as smoothly.

What is the purpose of a bill of materials?

The bill of materials primarily serves as a checklist of the materials or ingredients that are required to manufacture a particular product.

It allows workers and suppliers to determine whether all the necessary materials are available, which then enables them to plan and allocate resources effectively.

What does a bill of materials include?

The specific information in the bill of materials will vary depending on the type of project or product that’s being produced.

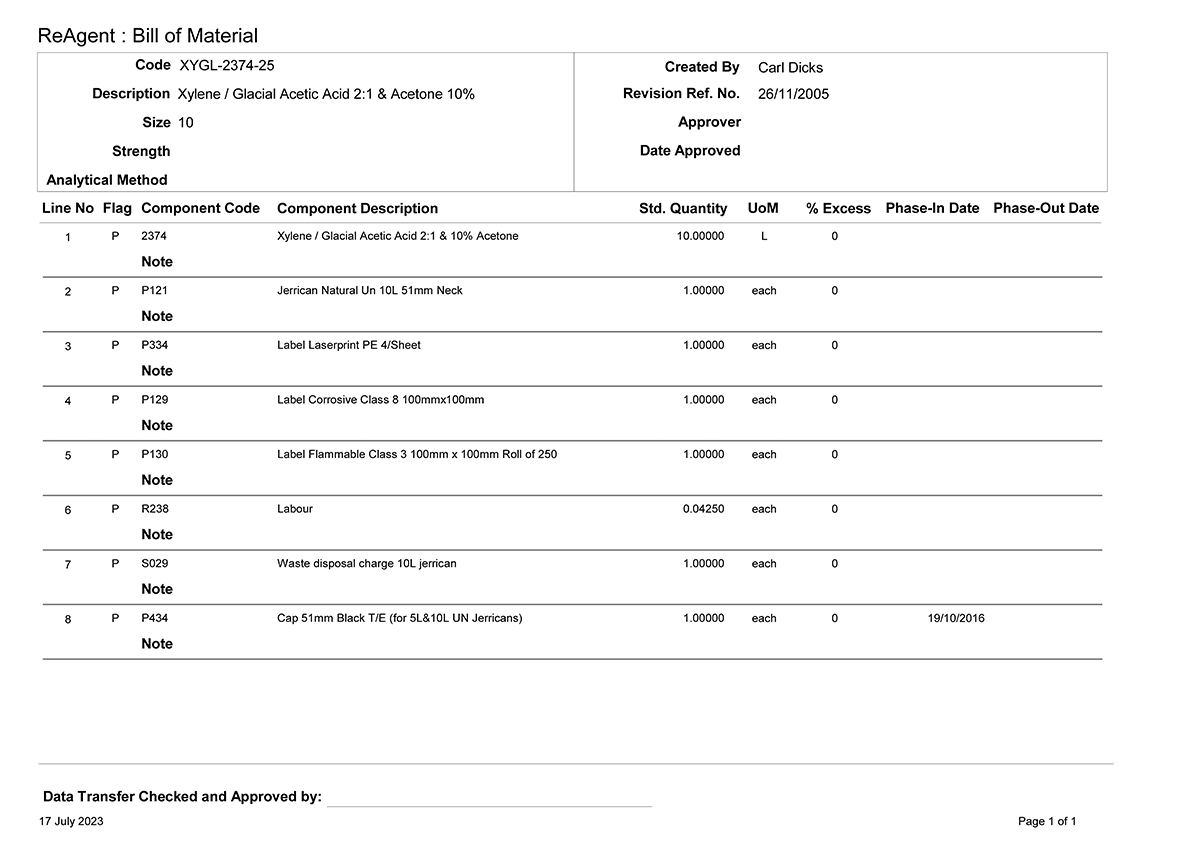

For example, the BOM for medicines may include chemical reagents, solvents, and catalysts. Again, the specific chemicals will differ depending on the type of medicine. That being said, some general sections that are included in all BOMs.

The bill of materials always includes a description of the materials required, along with the unit cost of each one. It may also contain a list of the suppliers. A product’s BOM is typically presented in a table form, as shown in the example below. The titles of the columns may vary depending on the project or product.

Raw materials

Many manufactured products and projects require raw materials. Generally speaking, these tend to be natural materials that are either unprocessed or partly processed. They usually need further processing before they can be combined to make a finished product.

For example, the raw materials of a concrete house include cement, sand, and gravel. These materials have to be combined and assembled in a certain way to build the various parts of a house, such as the foundations.

Subassemblies

Subassemblies are smaller components or units of a whole product that are made separately and then incorporated into the larger manufactured product during the assembly phase.

Examples of subassemblies are the various components of a car (such as the panels and body frame) in an assembly line. The subassemblies can either be manufactured internally or ordered from specialist suppliers.

Assemblies

Assemblies refer to larger, more complete products that have been manufactured from subassemblies. For example, in the chemical industry, it might be a biochemical product like a polymer or an enzyme that’s been created from subunits.

An assembly could also be a complex machine like an entire aeroplane, which consists of subassemblies from various suppliers around the world.

Parts & components

Many of the parts and components that make up a manufactured product are standard items like integrated circuits or chips, which are typically ordered from suppliers. Some of the parts and components listed in the BOM may also be included as spares for each unit of product. For example, drone products usually come with spare propeller blades.

Why is a bill of materials important in the chemical industry?

The chemical industry relies heavily on accuracy and precision. Knowing exactly how much of a particular ingredient or chemical is required is essential when producing certain products.

Having a bill of materials therefore allows chemical manufacturers like ReAgent to make high-quality, precise and accurate formulations that meet clients’ unique requirements.

Who is responsible for the bill of materials?

The bill of materials is normally prepared by a company’s procurement department. This division is usually responsible for overseeing the business’s inventory and providing suppliers with the information they need regarding materials. They may also compare offers from several suppliers to find the best deal.

Small businesses and professionals like architects, however, often have to prepare the bill of materials with the help of the client’s specifications. They may need to provide several quotes and will typically require their client’s approval before finalising the BOM.

Summary

The bill of materials is a centralised source of information that contains a list of the materials that are required to manufacture a particular product. It also includes detailed instructions on how to make and assemble that item.

A BOM is always prepared before production gets underway because it allows workers and suppliers to check the materials are available. While the precise details in the bill of materials vary depending on the product, all BOMs contain the same basic information such as the cost per unit and the number of units required.