Ampoule Filling Services for Various Industries

ReAgent has been providing ampoule filling services in the UK for almost 50 years.

Ampoules contain and protect small samples of a product. They are ideal for single-use applications, and for ensuring protection from the environment. The reason our ampoules are made from glass instead of plastic is that glass is impervious to gases and other contaminants.

Suppliers and clients alike can benefit from glass ampoule filling, with:

- Compatibility with a wide range of flammable and non-flammable liquids, including those sensitive to environmental exposure and other chemical solutions.

- Hermetic, airtight sealing that protects chemicals against airborne contaminants for a cleaner, safer, and longer preservation of the product

- Efficient transportation process

- Ampoules of more sensitive products can be nitrogen-purged to retain the highest quality

Why Choose Glass Ampoules

Widespread manufacturing of glass ampoules provides the perfect chemical packaging solution for businesses requiring single-use products. Their size, portability, and ease of use mean that ampoules have a wide range of uses. They can be used:

- For holding and preserving product samples

- As part of a product test kit

- As training materials in healthcare

- To hold air sensitive reagents

- To contain particularly hazardous liquids

- For standard reference materials

Our ampoules are often used in medical training. This is because a disposable ampoule is an efficient and accurate way to train students to prepare, calculate, and administer drugs. ReAgent manufactures glass ampoules for medical training programmes across the UK.

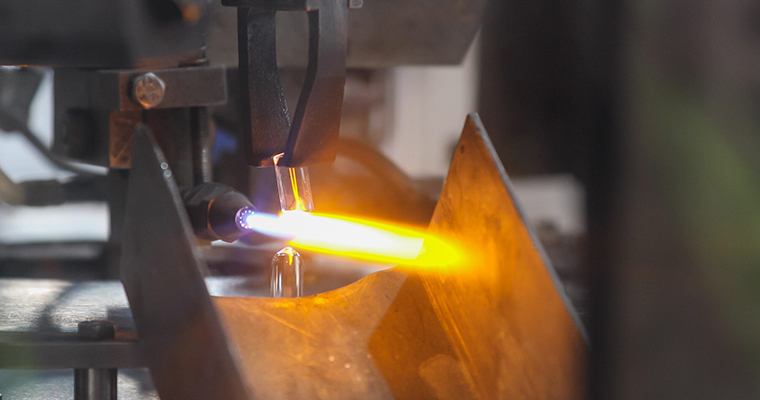

Our Glass Ampoule Filling Process

At ReAgent, our glass ampoules are filled using an automated ampoule filling machine. The machine uses a flame to melt the top off each individual ampoule, making it ready for filling.

The machine then injects the chemical into each glass ampoule, and a second flame hermetically seals it (meaning it makes the ampoule airtight) to protect the contents from external contaminants.

You can watch how we fill our ampoules in this video.

The team at ReAgent took the time to fully understand all of our needs before offering a solution. They made a potentially difficult project very easy. In a word: brilliant!

Nick Barker

Managing Director

Fast, Efficient & Reliable Ampoule Filling Services

Our state-of-the-art Rota 915 ampoule filling and sealing machine produces ampoules quickly and efficiently. If you need a fast turnaround, just let us know. The Rota 915 is capable of:

- Producing approximately 15 filled and sealed glass ampoules per minute

- Outputting over 8,000 ampoules per working day

- Providing a cost-effective method to meet your packaging requirements

- Filling an ampoule with 0-20 ml of most free flowing liquids

Finished ampoules can be supplied in bulk, as part of a kit, or packed into cartons of 5, 10, or 20 units. You can also buy off-the-shelf ampoules of pure water online.

Ready to discuss your requirements?

Call our technical sales team on 0800 9555 798

Filling Ampoules with Different Products

At ReAgent, we provide ampule filling services for a wide range of chemical liquids. These include, but are not limited to:

- Some acids in liquid states

- Some alkalis in liquid states

- Non-toxic liquids, for example, deionised water

- Toxic liquids

- Flammable liquids

Please contact us for more information and to discuss your ampule filling specific requirements.

Ampoule Filling Case Studies

ReAgent works with customers across a range of industries to supply high-quality, bespoke chemicals that suit their specific needs. Watch our case study videos to hear what some of our customers say about working with us.

Custom Product Development

- Free pre- and post-sales support

- Testing for consistent high quality

- Full regulatory compliance

Our Quality Accreditations

ISO 9001 Quality Standard

Proof of our commitment to our customers and team in providing high-quality chemical manufacturing services.

ISO 13485 Medical Devices Standard

We are among the top UK chemical manufacturers that also have accreditation for medical devices.

ISO 14001 Environmental Standard

Demonstrates our ongoing commitment to the environment, reducing waste and working in an environmentally responsible way.

ISO 45001 OHS Standard

We are committed to maintaining an OHS management system, eliminating hazards, and minimising OHS risks.

Eco-Friendly Ampoule Filling Services

ReAgent is an ISO-accredited company. Our ISO 9001:2008 Quality Standard means that our ampoule filling service is guaranteed to meet all your specifications.

As environmentally-conscious ampoule manufacturers, we dispose of any waste materials responsibly and with minimum impact on the environment. Our success in doing this is backed up by our ISO 14001:2004 Environmental Standard.

Trusted Ampoule Filling and Sealing Manufacturers

You can buy ampoules and have them filled with your product by ampoule filling and sealing manufacturers.

At ReAgent, we have more than four decades of experience in ampoule filling and sealing, and we can also work with you to create or manufacture the product contained within the ampoules.

Download our brochure

Find out more about our chemical manufacturing services, facilities, and accreditations.

Why Choose Our Ampoule Filling Services?

Always open for customer audits

We believe that a solid foundation of trust is fundamental in any business relationship. One of the reasons we are such a well respected and trusted ampoule supplier is because we open our doors to customers, allowing them not only to come in and talk to us face to face, but to audit our facilities and make suggestions for improvement.

100% focused on customer value

Continuous improvement is what drives our business and this is led by our unwavering focus on providing the best possible value to our customers. We always implement changes that will impact positively on this at all levels of our operation.

ISO 9001:2009 Quality Standard

Every ampoule we manufacture is backed by our internationally recognised ISO quality standard. This means we guarantee that the products we manufacture for you will meet your specifications.

ISO 14001:2009 Environmental Standard

As a responsible ampoule manufacturer it is our duty to care for and respect the environment, especially as many of the products we manufacture are hazardous. This is a responsibility we take very seriously at ReAgent and our ISO 14001 Environmental Standard is proof of that.

Ampoule Filling FAQs

We can fill most liquids into ampoules, including corrosive and flammable liquids.

In order to be cost-effective, our minimum order quantity is 1000 ampoules.

Yes, we can handle organic products for ampoules as long as they are liquid.

We will certainly look into certifications that you may require for filling ampoules.

Yes, all our ampoule filling services and packaging can be completely customised to suit your needs.

We can currently fill glass ampoules in sizes ranging from 1ml to 20ml. We can fill various volumes from 0.2ml to 20ml.

Yes, we specialise in chemical blending and can manufacture bespoke formulations to suit your requirements.

Yes, we can provide contract manufacturing services for ampoule filling. Please call our friendly sales team on 0800 9555 798 to find out more.

Yes, we can ship filled ampoules internationally from the UK.

The lead time for ampoule filling is dependent on the quantity of ampoules you require. A typical lead time for an order of 10,000 ampoules would be 10 working days.

To get a quote for our ampoule filling services, please call our sales team on 0800 9555 798.

Need High-Volume Chemical Bottling?