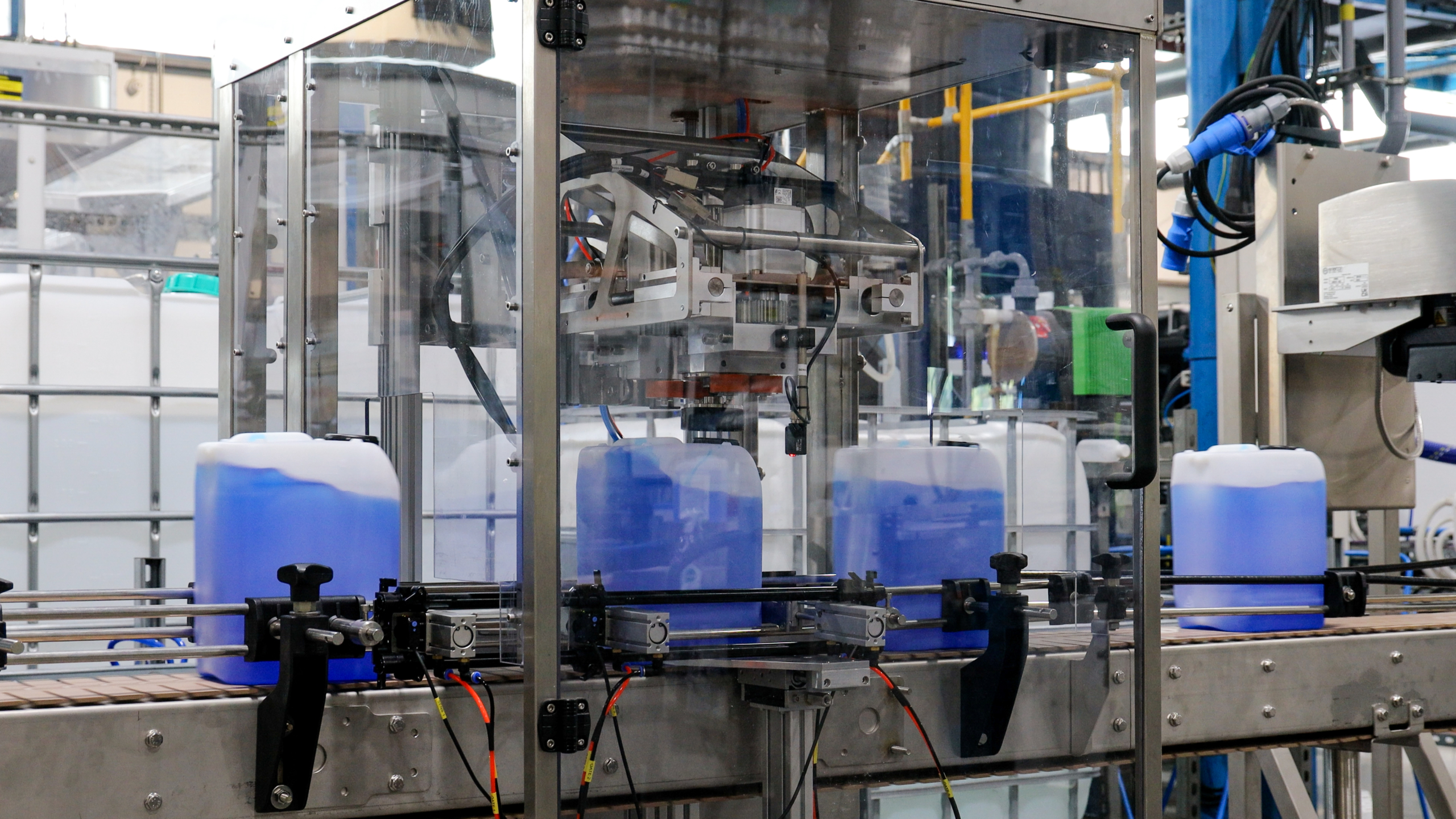

We’ve added a powerful new asset to our factory floor: a fully automated filling line designed for high-volume, high-accuracy chemical filling.

Watch it in action in our latest video to see the process from start to finish:

This line is built to meet the needs of customers who require large volumes of chemical products filled, sealed, and labelled with speed and precision.

Read on to see how the line works, the equipment it includes, and what that means for your product.

In this post:

How our Automated Filling Line Works

Our automated filling line connects directly to IBCs and bulk tanks, allowing us to handle high-volume runs without interruption. This closed transfer method helps maintain product integrity while increasing output.

The process begins at the in-feed table, where bottles are continuously supplied to a four-head filling system. Each stainless steel head features diving nozzles for bottom-up filling, which reduces foaming and prevents spillages.

After filling, caps are applied and tightened automatically. Every cap is torque-checked in real time, with measurements between one and 14 Newton-metres to ensure a consistent, secure seal.

An optional induction heat seal can be applied using electromagnetic induction. This process welds a foil over the bottleneck without any physical contact or open flame, providing a tamper-evident seal and extended shelf life.

We use a high-speed inkjet coder to apply up to six lines of text, barcodes, or a combination of both to each unit. Our labeller accommodates a wide range of container types, applying front-and-back labels, wraparound designs, and trigger spray formats at speeds over 30 bottles per minute.

After labelling, bottles are boxed, sealed, and palletised. Full batch traceability is maintained throughout the process, supporting quality assurance and regulatory compliance.

Technical Specifications and Capacity

We can fill both cylindrical and square containers ranging from 500 ml to five litres.

Depending on the pack size, the line can achieve:

- Up to 1,440 litres per hour for 1-litre bottles

- Up to 4,800 litres per hour for 5-litre bottles

- That’s over 115,000 litres per day on a continuous 5L run

Material Compatibility

All wetted parts are made from 316 stainless steel, allowing us to fill a wide range of aqueous chemical products, including:

- Alkaline solutions

- Weak organic acids such as dilute acetic and lactic acid

Flammable products are not currently filled on this line, in line with safety protocols and material compatibility.

Designed for Flexibility and Efficiency

The system is optimised for fast product changeovers. Easy-clean components and optional inline filters minimise downtime between batches, while quick mechanical adjustments make it simple to switch between container types and label formats.

All processes are governed by our ISO 9001-certified quality management system. We also hold ISO 14001 and ISO 45001 certifications, which underpin our environmental and occupational health and safety commitments.

Whether you’re a small business scaling up or a multinational with complex technical requirements, our automated filling line is equipped to support your production needs.

Want to know more? Contact us today to discuss your project.